FGD-Suspension Separating Method

In May 2017, THE ANNOUNCEMENT ON THE IMPLEMENTATION OF SPECIAL EMISSION LIMITS OF ATMOSPHERIC POLLUTANTS IN BEIJING, TIANJIN, HEBEI AND THE SURROUNDING AREAS, established by the Ministry of Environmental Protection of China, stipulated that the existing enterprises in "2+26" cities should implement the special emission limits of atmospheric pollutants from October 1, 2017. The special emission limits (GB25465-2010 revised list) of atmospheric pollutants for aluminium industry are implemented in electrolytic aluminium industry, i.e. dust concentration 10mg/Nm3, fluoride concentration 3mg/Nm3, SO2 concentration 100mg/Nm3.

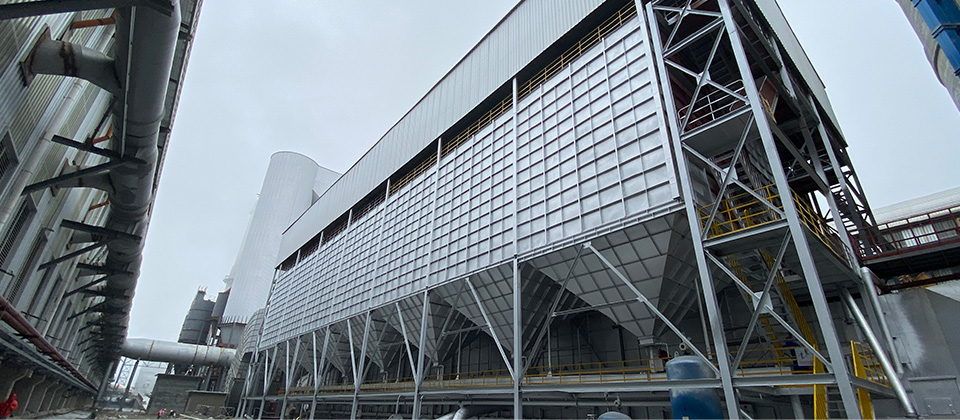

FGD-Suspension separating method is a desulfurization process that we created and offered to the majority of users based on a large number of experiments in combination with the characteristics of electrolytic flue gas. The desulfurization process has many advantages, such as less one-time investment, simple process, convenient maintenance, no waste water discharge, no visible white smoke plume at the stack (i.e. saturated water vapor) thus no additional treatment required, and the emission index achieved is obviously superior to the national standard.

The desulfurization process is also applicable for carbon, power and other industries.

No.2 Process Introduction

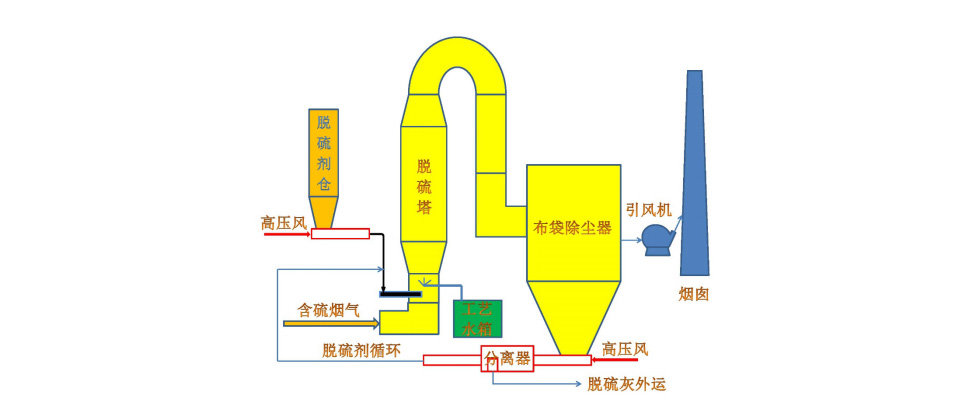

Cao / Ca (OH) 2 is used as desulfurizer in the suspension separating desulfurization process. The Ca (OH) 2 desulfurizer is conveyed to the FGD reaction tower to react with SO2 in the flue gas. After the reaction, the flue gas enters the bag filter to separate CaSO4 and a small amount of Ca (OH) 2 from it then the gas is discharged into the atmosphere through the chimney. The separated Ca (OH) 2 returns back to the FGD tower through the circulation system for reaction again. This system continuously separates and circulates to achieve the best utilization rate of raw materials and the best desulfurization effect. The final desulfurization product CaSO4 is conveyed to the desulfurized waste storage bin through the pneumatic conveying system.

The principle of the suspension separating desulfurization process

Adsorption reaction:

SO2 + Ca (OH) 2 (solid) + 0.5o2 + H2O = CaSO4 ? 2H2O

The desulfurizer Ca (OH) 2 finally will be nitrated. The structure of the suspension separating desulfurization system is simple. It is a process that saving energy and protecting environmental, easy to operate and manage, no corrosion to equipment, no waste water and no secondary pollutants.

No.3 System Composition

The FGD-Suspension separating method system mainly consists of: FGD tower, bag filter, process water system, hot air heating system, desulfurizer conveying system, waste material conveying system, circulating material conveying system, duct and valves, and electrical and automatic control system etc.